MOBILE PATCHING BATCH ASPHALT PLANTSpotMix 300

The ideal asphalt plant for surfacing car parks, small areas of road or road maintenance jobs.

SpotMix is capable of producing up to 18 tonnes of coated mixed material per hour.

For smaller projects, see the SpotMix 150 .

The latest version of the ‘Spot-Mix’ 300 is the MKIII, with features which include a new improved drive arrangement, easier on-board bitumen management and a more fuel efficient burner system.

This compact and highly mobile plant is ideal for on-site production of quality asphalt for smaller surfacing duties, especially in less accessible and confined localities, car-parks, small areas of road or road maintenance jobs.

Features

The model shown also incorporates on-board electrical generator.

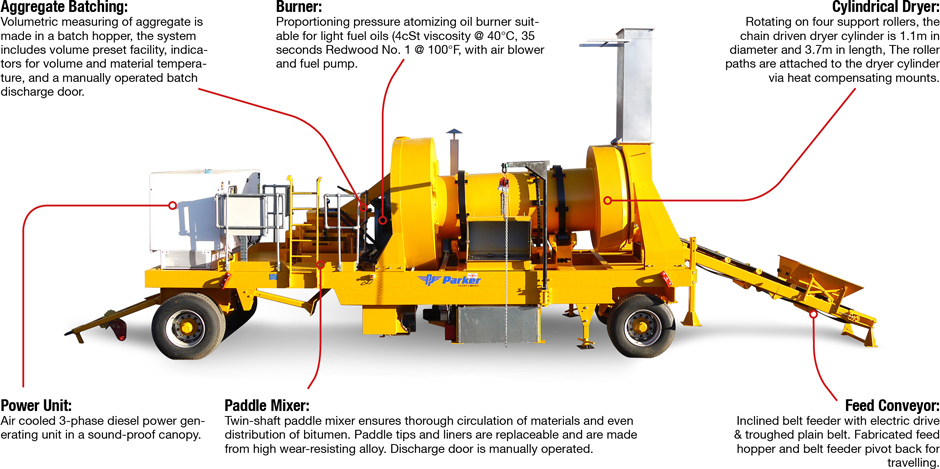

Aggregate Batching

Volumetric measuring of aggregate is made in a batch hopper, the system includes volume preset facility, indicators for volume and material temperature, and a manually operated batch discharge door.

Burner

Proportioning pressure atomizing oil burner suitable for light fuel oils (4cSt viscosity @ 40°C, 35 seconds Redwood No. 1 @ 100°F, with air blower and fuel pump).

Cylinder Dryer

Rotating on four support rollers, the chain driven dryer cylinder is 1.1m in diameter and 3.7m in length, the roller paths are attached to the dryer cylinder via heat compensating mounts.

Power Unit

Air cooled 3-phase diesel power generating unit in a sound-proof canopy.

Paddle Mixer

Twin-shaft paddle mixer ensures thorough circulation of materials and even distribution of bitumen. Paddle tips and liners are replaceable and are made from high wear-resisting alloy. Discharge door is manually operated.

Feed Conveyor

Inclined belt feeder with electric drive & troughed plain belt. Fabricated feed hopper and belt feeder pivot back for travelling.

Bitumen Decanting & Storage

Integrated bitumen decanting, heating and storage, includes insulated and clad storage tank that rolls outwards when in operation, drum lifting davit and drum hood for decanting bitumen, oil burner for transfer of heat through heating tube and integrated exhaust stack, bitumen pump, temperature gauge and bitumen ring main.

Bitumen Weighing

Bitumen weigh gear measuring trough is manually pivoted and calibrated for measuring different volumes of bitumen directly into the paddle mixer.

Options

- Bitumen supply tank

- Integral chassis-mounted powerpack