SPARE PARTS, SERVICE & SUPPORTParker Genuine Spare Parts

The reliability and performance of your Parker equipment should never be compromised by the fitting of non-original spare parts or components.

Parker replacement parts are made to the same exacting standards and are subjected to the same rigorous testing as the original equipment used on all Parker installations worldwide.

At our Leicester works we offer the only source of genuine spare parts covering the complete range of our equipment. More than 12,000 different line items are continually held in stock. Our computerised record systems are able to identify requirements for Parker equipment spanning in excess of the last 50 years, whilst our order processing and dispatch are able to satisfy a high percentage of customer orders directly from stock.

As the original manufacturer we can also offer a complete range of parts manuals, installation and maintenance instruction and technical literature to assist with getting the optimum out of your plant.

Our Parts Team is on hand to deliver a speedy and friendly service and ensure your plant is back up and running in the shortest possible time.

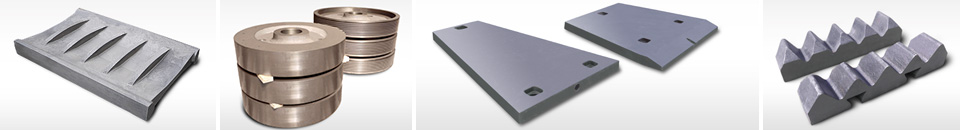

Jaw Crusher Parts

Parker Plant stock a full range of jaw crusher replacement parts suitable for use in the ‘StoneSizer’, ‘RockSizer and ‘RockSledger’ models.

We supply spares for stock fixed and jaw swing liners, flywheels, cheek plates, wedges and much more for all sizes of Parker crushers including the 1300 x 1050, 1100 x 800, 1100 x 650, 1000 x 600, 900 x 600 and 800 x 500 jaw crushers.

Impact Crusher Parts

We stock premium quality spare parts and wear parts to suit a wide range of Parker HD horizontal Impactors as well as the Parker ‘Kubitizer’ which is renowned around the world for its reliability and performance.

Parts available include motors, hammers, rotors, vee belts, liners and hydraulics components.

Screen Parts

Replacement parts are available for all Parker screens including the ‘Rapide’ and ‘ScreenRanger’ models.

With screens being vigorously used on a day by day basis we acknowledge the fact that sometimes they can fail and spares are required immediately, we therefore ensure that we stock a wide variety of meshes, bearings, housings and screen shafts to get you back up and running as quickly as possible.

Asphalt Plants Parts

Parker Plant stock a large number of asphalt plant proprietary items and premium quality manganese castings to assure continued to support to our customers long after a plant has been delivered, installed and commissioned.

A team of dedicated parts co-ordinators is available to offer a rapid response, friendly advice and technical support to ensure correct parts selection and reduce costly downtime.

Asphalt plant spares includes items such as paddle mixer arms, tips, liners, bearings, shafts, elevator buckets, sprockets, filter cages, filter bags, belt feeders, idlers, pneumatic equipment and much more to suit asphalt plants like the ‘Super-Blackmobile’, ‘Super-RoadMix’ ‘StarMix’, BlackMix’ and ‘BatchMix’.

Conveyor Parts

On demand and in stock, Parker Plant stock all spares for conveyors and associated material handling equipment, including conveyor belts, idlers, rollers, drums and spiral drums.

See our conveyor component page for a detailed list of conveyor spares.

Service & Support

With over a century of experience in supplying aggregate processing solutions and asphalt mixing plants to remote areas around the globe we know the significance of maintaining plant productivity.

At the design stage of every product, Parker place considerable importance on ease of maintenance, increased component accessibility and simplicity of component removal or replacement. These are major factors often overlooked by others, that if not considered carefully can adversely affect the long term plant performance and productivity.

Parker’s experienced, fully trained service team, is there to offer help and assistance throughout the lifetime of your equipment. Arrangements can also be made for inspection visits to offer guidance on plant productivity performance, parts replacement, plant upgrades or long term maintenance contracts can be agreed to provide service support visits to a planned schedule as required.

Specific areas can be assessed such as burner performance on asphalt plants or plant productivity and component wear characteristics of crushing plants.

InformationFind Out More

Download our range of brochures below or call our experts to discuss your requirements.