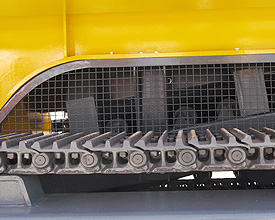

Tracked ConesSecondary or Tertiary Tracked Cone Crushers

Featuring the GC cone crusher for maximising production; they are renowned for achieving significant rates of reduction, cubical product shape and providing high quality aggregate and sub-base material. The GC series can also be fitted with a recirculating conveyor and single deck screen to further reduce oversize material in a complete pass.

- Robust and durable crushers featuring rapid setup times

- High throughput capacity and large reduction rates

- Hydraulically adjustable crusher settings

- Advanced electronic control system interface

- Easily accessible maintenance and service points

- Simple hydraulic circuits

- Efficient CATERPILLAR® powerpack designed for low operating cost

- Global aftersales service, support and spare parts supply